Plastic Injection Molding Services by BMI

Prototype, Short Run, or Volume Production, our 100 to 600 ton Plastic Injection Molding capability provided by state of the art Molding machines and process controls will meet your project requirements.

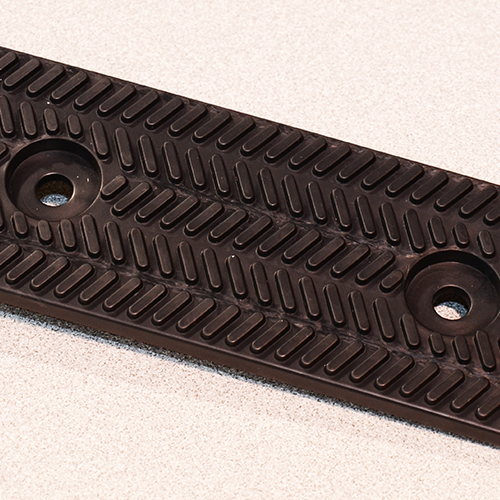

Serving the Automotive, Medical, Industrial, and Consumer markets, our high quality Plastic Injection Molded products consistently exceed customer expectations.

BMI Injection Molding & Assembly is available to review your Injection Molded product application and recommend:

- Thermoplastic Resin recommendations utilizing our network of resin professionals

- Design recommendations to insure product performance that exceeds requirements

- Product design review to insure maximum manufacturability for Plastic Injection Molding, and Assembly Processes

High Tolerance prototype to production Injection Mold builds performed by BMI's approved domestic tool facilities allow us to provide you with a total Injection Molded component solution, from product design assistance to finished production Injection Molded components and assemblies.

BMI’s engineering based competitive business statement, along with our comprehensive tooling and secondary operation services insures your Injection Molded project will be delivered on time, every time.

We specialize in Value Added Plastic Injection Molding that yields an assembled component by including the Injection Molding process within the product assembly work cell.

Our capacity molding statement allows our customers to recover valuable Injection Molding utilization by taking advantage of our competitive outsource rate for over capacity projects.

Some of the turnkey services in this area provided by BMI, Chesterfield, MI near Detroit, MI:

plastic injection molding Michigan, plastic injection molding process, plastic injection molded parts, custom plastic injection molding MI, plastic injection mold design, plastic injection molding manufacturers, plastic injection molding Michigan, plastic injection molding design, plastic injection molding services, injection molded plastics, plastic injection molding materials, automotive plastic injection molding Detroit, Michigan, medical plastic injection molding Detroit, MI